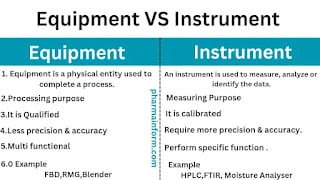

People working in pharmaceutical industries are frequently using the term equipment & instrument In their routine work & many of us think that both terms have the same meaning.

But the fact is not as we think.

Technically there is a big difference between these two teams and In this article, you will learn the key differences between equipment and instrument.

Equipment

Equipment is a physical entity or machine which is used in pharmaceutical industries to complete a process or activity.

Example

Example of equipment used in pharma is,

- FBD

- RMG

- Blender

- Compression Machine

Multifunctional

Equipment may be used

to perform more than one function like RMG is used for pre-mixing as well as kneading.

Percussion & Accuracy

Equipment concept of precision & accuracy is less stringent compared to instruments.

Calibration

The equipment is not calibrated

Qualifications

As we discussed earlier no calibration for equipment means the exact term used for equipment is qualification.

In simple words, equipment is qualified, not calibrated.

Maintenance

The equipment maintenance plan is not strict.

Footprint

Equipment occupies more space like a fluid bed dryer.

Processing

Equipment is used for processing or manufacturing.

Example

FBD is equipment which is used to dry the granules.

Lubrication

Equipment usually requires lubrication to avoid any serious damage to its parts.

Compression machine has a lubrication pump to ensure lubrication of required parts.

Instrument

An instrument is a device which is used to measure, analyze or identify the data.

Example

Example of instrument,

- pH meter

- HPLC

- FTIR

- Moisture Analyser

No Multifunctional Role

Instruments are used for a specific task.pH meter is only used to measure the pH.

Percussion & Accuracy

The instrument requires more precision & accuracy to ensure accurate results.

If the pH meter is not accurate the results obtained will not be precise and accurate.

Calibration

The instrument requires frequent calibrations to assure accurate results.

Qualification

Instruments are not qualified, rather these are calibrated.

Maintenance

The instrument maintenance plan is very strict because if maintenance is not conducted on time, the results obtained may be objectionable.

Footprint

Instruments occupy less space e.g HPLC

Measuring

Instruments are used for measuring the results of products processed by the equipment.

Example

A moisture analyser is an instrument which is used to measure the moisture in the granules dried by a fluid bed dryer.

Lubrication

Instrument does not require lubrication.

Also Read

Difference between disintegration & dissolution.

Very informative.